Our Fused Glass

I have to say, the glass has little to do with us goats. We don’t actually make the glass, our humans do. Making glass is hot work. I don’t like hot, or work. I see no reason to interrupt a perfectly good day of eating, sleeping, and playing in our field to make glass.

However, I was told some who come to this website want to know about our glass. Ok, fair enough. First, us goats asked the humans about how to make glass. When they were telling us, we got bored and ran off to play in the field. So we told them to write it down. While reading it, we got hungry, so we ate it and went to play in our field.

So, we asked them to just tell you. It will probably be really boring, so we intend to eat, sleep, and play in the field.

It all starts with flat sheets of glass. It is special glass that expands and contracts under heat at the same rate. if it didn’t, all our pieces would explode from the internal stress while cooling. There are just a few factories in all the world that make this special glass. Luckily, two are just about an hour from our studio, more or less.

We proudly use Wissmach Glass from Paden City, WV and Youghiogheny Glass from Connellsville PA. We can choose each piece ourselves from the factory and bring it home without shipping, to keep our cost down and our money local. Occasionally we must buy other glass because we need a color they don’t make, or have on hand.

We use every sliver of glass no matter how small.

The other thing we need is kilns.

At Goofy Goat Glass we have four kilns. All of them reach a minimum of 1500 degrees Fahrenheit, which is more than enough to melt glass. They are also all computer controlled and programmed to make sure the glass does not heat up or cool down too quickly. They are also programed to aneal the glass properly, so your piece does not have stress fractures from uneven cooling, like if the outside cools faster than the inside. We want each piece we hand make to be perfect.

The four techniques of glass making we do in kilns are slumping, tack fusing, full fusing, and casting.

Each piece we make starts out flat. If the piece you buy is dimensional and not flat, it means as its last step it was slumped.

Slumping is when we heat the glass to 1200 to 1300 degrees fahrenheit and have it over a mold. At that temperature the glass does not yet melt, but it does become plyible. The surface will become shiny (or heat polished) and it will be pulled into or over the mold by gravity.

Here you see one of our seasonal items, a ghosty, in the kiln as flat pieces of glass, then slumped over a mold. We place them over an electric tea light when finished.

The second technique is tack fusing. In tack fusing we heat the glass to 1350 to 1375 degrees fahrenheit so that the surface melts but the center remains solid. This allows the pieces stacked on the glass to melt together yet stay with clearly defined layers.

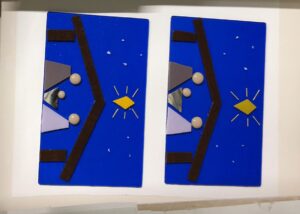

Here you see the technique demonstrated with our seasonal nativity. The piece is displayed on a handmade custom hardwood stand, also made here at Goofy Goat Glass.

The third technique is full fusing. In full fusing we heat the glass to over 1400 degrees fahrenheit. At that temperature, the glass will fully melt to a liquid form. The glass on the top will melt into the base glass and appear as a design on the glass even though it is smooth on top.

The round piece here will be slumped to either make a bowl or a platter before being sold. The top piece of glass is a special piece of fuser reserve glass from Oceanside. Each piece is unique in design and it is a very expensive piece of glass. So when I hit it with a hammer to make this piece, My wife shudders a bit.

The last technique is glass casting. This is what we do with all the little bits we have left over from bigger projects and pieces that came out of the kiln and either cracked in the process or were not good enough to be sold under our name. The pieces are broken up into small pieces and placed in our molds. They are heated to a full fuse and cooled very slowly because they are so thick.

This piece shown is one of our pocket hearts. It is either tack fused to a background and sold in a frame or left loose. All our loose pocket hearts come in an organza bag with a note inside.

What? You are still here? Violet warned you it was boring. Well, now you know how they make each piece and when you see them ask them whatever questions you have.

Be sure to stop by their tent at shows or their booth at one of their store locations and see the items they make for yourself!

Make sure you buy something when you are there. We eat a lot.